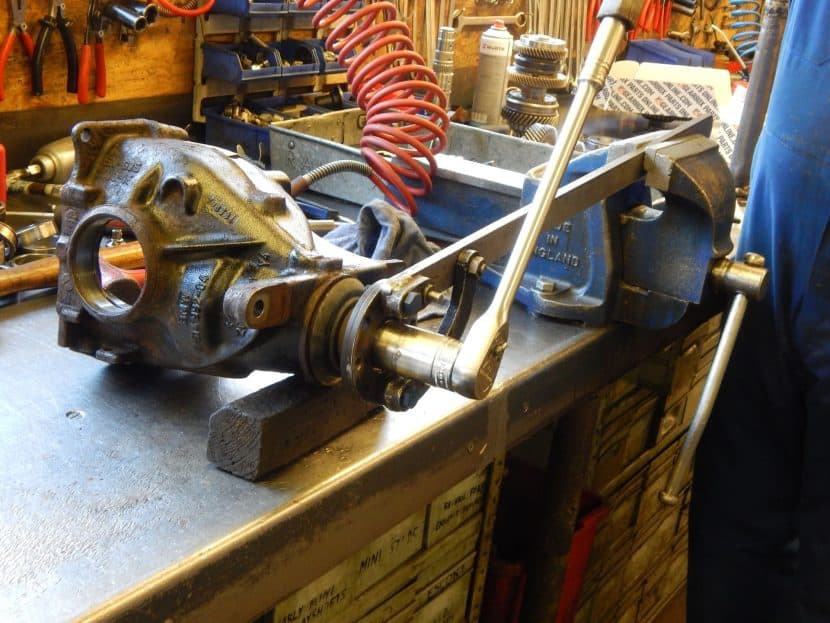

The small case 168 differential on the four-cylinder petrol BMW 1 Series and E90 3 Series ranges is a bit troublesome. There is no obvious reason for this to be so – it is a very well-made unit, machined to incredibly fine tolerances, and uses bearings from well-respected manufacturers. However, many begin to whine by 70,000 miles and can get really noisy. While it is rare for a diff to fail, I recently replaced a diff in a 2008 BMW 320i Coupe (E92) that was close to a big failure and a loss of drive.

About the Type 168

The Type 168 has been BMW s small diff forever – the smaller-engined E30, E36, and E46 cars used this diff size, and the 168 apparently refers to an internal measurement. The medium-size diff is the Type 188 and the really big one is the Type 210.

The 168, first fitted to the 2004 1 Series – 116i, 118i, 120i, and the 04-07 Euro 118d – differs from the previous E46 type unit in one major respect: it replaces the previous taper roller bearings for the pinion and crown wheel side bearings with ball bearings. This was done to reduce friction and make the diff easier to turn – which is noticeable when you have the older and newer type diffs side by side. Also, the oil used was a much thinner synthetic 75/90 as opposed to EP90.

Lastly, the sun and planet gears used in the actual differential unit are sintered steel, doubtless cheaper to make than the older type gears used in E30 and E36 units. This diff was also used in the E90 3 Series – in Europe the 316i, 318i, and 320i plus in the U.S., the 323i.

What Goes Wrong?

Much of the blame can be attributed to the lack of a drain plug for the diff and no official oil change interval. The factory fill oil is there forever unless you have a tool to draw the old oil out, and nobody ever bothers.

While the differential side bearings very rarely wear, the pinion ones certainly do, with the smaller end bearing nearest the driveshaft flange being the worst. BMW used three bearing manufacturers: INA, FAG (German), and Koyo from Japan. I ve rebuilt several diffs and found that the newer the car, the more likely it is to have noisy bearings. They are undoubtedly very high quality but seem less able to cope with long-life diff oil. The sintered sun/planet gears also start to pit and eventually break up.

Can I Rebuild My Differential?

Yes, but they re difficult, requiring both a very good tool kit and a ˜feel for things mechanical. The differential assembly is secured into the iron diff housing with a big circlip each side, and these double up as shims to set the crownwheel and pinion lash correctly. The pinion bearings are very hard to remove and replace. Once the pinion is out, the big and small bearing outer cages need to be driven out using a mixture of brute force and careful skill. Refitting the new big bearing outer cage is really hard work, and I ve found the best way is to heat the casing in very hot water and have the bearing cage in the freezer. There is a spacer shim under the bearing cage as well, and during bearing removal it s very easy to mark the soft cast iron diff casing – this must be rectified, or the new bearing will not sit correctly.

Think that s bad? Now you have to get the big bearing inner cage off the pinion, and it s pressed on with several tons of force. A puller will not grip it, so you have to carefully grind away enough of the bearing cage until it splits on its own without marking the pinion.

Then you have to fit the pinion with the new crush tube and set it up. Sound like fun?

How Do I Tell A Good One From A Bad One?

Easy. Turn the pinion flange, and the turning motion should feel pretty smooth. If it feels rough, noisy, or graunchy, it s scrap. Get the right diff as well. The 168 unit has seven bolts securing the rear alloy cover, and the prop flange is circular with four bolts. Look on the white top sticker, and you can see the ratio and part number. The various ratios are 3.91, 3.73, 3.64, 3.45, 3.38, 3.23, and for the 118d, 2.47. Put the VIN from your car into Realoem, and you can find out what diff your car has.

Cars with auto stop-start can be very fussy on ratios. Fit a car that had a 3.64 from new with a 3.91 or a 3.23, and the car s ECU will pick up the difference in road/engine speed and object, rendering the cruise control inoperable and often putting the car into limp home mode.

Can I Make A Whining Differential Last Longer?

Debatable, but an oil change won t hurt. Draining the old oil and refilling with something like EP90 or even EP140 (good thick stuff) can often quieten down an ailing diff and make it last a bit longer, but once they are really howling, it s the end of the road. If your diff is still good, an oil change will help its chances, and many BMW specialists recommend a synthetic 75W/140 oil at around 13 quid a litre – just short of the 1.1-liter capacity, but you ll always have a bit of the old stuff in the diff you can t quite suck out.

Can I At Least Replace It Myself?

Sure – it s a three-hour struggle for a beginner or less than half that on a ramp for a BMW pro. It is secured to the rear subframe by two 18 mm bolts (use plenty of Plus Gas on cars from damp climates) and a single 21 mm rear bolt and nut. The output shafts are secured by six E12 Torx bolts on each side and the driveshaft by four E12 Torx. You ll find that the driveshaft is still stuck to the diff with the bolts out – DO NOT strike the side of the driveshaft with a hammer to free it as you will damage it. Instead, use a hammer and chisel to drive it off the diff flange longitudinally (towards the front of the car) while turning the driveshaft to free it off evenly.

The diff is heavy at 30 kg, so you will need to use a jack to lift it while inserting the three bolts. Replace the 16 driveshaft Torx bolts with new ones or use thread locking fluid on the old ones and torque them to spec.

Part Numbers

BMW diff part numbers are often one digit out on original fit and replacement (supersession) numbers. BMW swapped diffs around from model to model, and it would take a month of Sundays to list what each model had fitted. Again, realoem is your friend, so enter the last seven digits of your VIN to see what diff it should have. This is a guide to diff part numbers and supersession numbers plus some of the cars they were fitted to.

[Top Image: Andrew Everett]

First published by https://www.bmwblog.com